1-Bromopentane: Shaping the Backbone of Alkylation Chemistry

Historical Development

Tracing the journey of 1-bromopentane brings up nearly a century of synthetic organic chemistry. Early brominated alkanes surfaced in the 19th century labs, where August Wilhelm von Hofmann and other pioneers explored halogen-substituted hydrocarbons to unlock new organic reactions. By the early 20th century, 1-bromopentane started showing up in industrial catalogs, driven by its popularity as an alkylating agent. Each innovation in separation and purification technology made it easier to prepare, and its value kept growing as its applications widened, cementing its role in research and production settings alike.

Product Overview

1-Bromopentane, sitting in the family of primary alkyl halides, has built its reputation as a reliable reagent for introducing five-carbon chains into organic molecules. Chemists and manufacturers count on its predictable behavior in nucleophilic substitution reactions, opening the door for efficient alkylation not just in academic research, but for scale-up operations across pharmaceuticals, fragrance intermediates, and specialty polymers. Whether blending into the aroma of a designer solvent or setting the stage for a novel drug precursor, 1-bromopentane’s role goes beyond the bottle — it facilitates pivotal transformations across multiple sectors.

Physical & Chemical Properties

Looking at the clear, colorless to faintly yellow liquid, it’s easy to underestimate. With a molecular formula of C5H11Br and a molar mass of 151.05 g/mol, 1-bromopentane carries a distinct sharp odor reminiscent of other alkyl halides. Its boiling point, hovering around 129°C, suits distillation setups well without requiring extreme temperatures, and its relatively high density (1.18 g/cm³ at 20°C) makes phase separation with water hassle-free. Solubility remains limited in water but plentiful in organic solvents like ether or ethanol, reflecting the hydrophobic character of longer alkyl chains. This blend of volatility and immiscibility keeps handling straightforward under chemical hood conditions.

Technical Specifications & Labeling

Most reliable suppliers market 1-bromopentane at purities exceeding 98%, with key impurities like 2-bromopentane and pentan-1-ol fingerprinted by GC to ensure batch consistency. Labels mark it with CAS number 110-53-2, UN 2344 for transport, and the GHS pictogram for acute toxicity-flammability. Storage recommendations highlight cool, dry and well-ventilated areas, away from heat sources and strong bases, to stave off decomposition. Containers bear tightly fitted caps and inert gas overlays where stability needs reinforcement, reflecting the recognition of brominated alkyls as chemicals demanding respect — especially in volume work.

Preparation Method

Production, whether on the benchtop or at industrial scale, typically starts from 1-pentanol. The classic route swaps the hydroxyl group for a bromine atom via treatment with a brominating agent like phosphorus tribromide (PBr3) or hydrobromic acid (HBr). PBr3 offers a cleaner conversion with less chance of rearrangement, making it preferable in purity-focused applications. In some plants, hydrobromic acid with sulfuric acid catalysis holds an edge for simplicity and cost. Advances in green chemistry have prompted interest in solvent minimization and recycling, with some teams exploring phase-transfer catalysis or even continuous flow reactors to enhance yields, reduce waste, and bump up overall efficiency.

Chemical Reactions & Modifications

Among all primary alkyl bromides, 1-bromopentane stands out for its reliability in nucleophilic substitution reactions, including SN2 displacements that extend carbon skeletons without branching or rearrangement. Chemists take advantage of its reactivity to synthesize ethers, amines, thiols, and Grignard reagents with five-carbon chains, establishing a ready route to pentyl-substituted products each time. Bumping up complexity, this compound reacts with sodium metal to produce pentylsodium, a less common but powerful organometallic used in specialized research. Hydrodehalogenation provides an entry to pentane, and coupling reactions allow attachments to aromatic systems. Modifications can tune the pentyl group’s reactivity or substitute the bromine to yield more elaborate building blocks, fueling a cascade of downstream synthetic steps.

Synonyms & Product Names

1-Bromopentane crops up under several names in catalogues and databases, reflecting both IUPAC conventions and trade habits. Synonyms include n-pentyl bromide, pentamethylene bromide, and pentane, 1-bromo-. Regional usage or supplier traditions sometimes shorten it to simple “pentyl bromide.” Regardless of alias, the chemical’s identifier stays consistent: CAS 110-53-2, EC 203-782-9, UN 2344 in shipping manifests, and “Highly flammable liquid and vapor” stenciled across drums in any modern warehouse.

Safety & Operational Standards

Working with 1-bromopentane poses recognizable risks, so any lab or plant using it needs strong safety protocols. Direct contact with skin triggers irritation, breathing vapor may cause respiratory distress, and accidental ingestion spells trouble. Proper ventilation, gloves, goggles, and flame-resistant lab coats form the first line of defense. Storage facilities must control potential leaks, avoid ungrounded electrical sources, and keep incompatible substances — like strong oxidizers, alkali metals, or finely divided aluminum — far away. Emergency procedures emphasize evacuation, containment, and medical response, laying out specific measures for fire or significant releases. Waste handling routes empty barrels and wipes through approved incinerators or specialist hazardous waste contractors, keeping environmental risk in check.

Application Area

Each field finds its own reason to call on 1-bromopentane. In pharmaceutical circles, its alkylating power forms the basis for molecules that tackle everything from pain to infection. Fragrance designers use it to slip pentyl chains into esters, lending scents a richer backbone that holds through wear. Polymer researchers count on it during modification steps, feeding in five-carbon links to adjust flexibility or glass transition temperatures of specialty plastics. Its straightforward chemistry also makes it a staple in undergraduate teaching labs, where it recruits the next generation of chemists for SN2 exploration. Transfer agents in solvent extraction processes and intermediates for pesticides round out a portfolio that has only expanded with time and imagination.

Research & Development

Researchers chase new uses and safer handling methods every year. Current work documents the switch to less hazardous brominating agents, replacing PBr3 with eco-friendly alternatives while maintaining yield. Analytical chemists have mapped out precise impurity profiles using high resolution GC-MS, cutting down on surprises when scaling to pilot level. Interdisciplinary teams focus on getting more out of each molecule: using computational chemistry to predict reactivity, or developing engineered biocatalysts capable of selective bromination or dehalogenation. These advances drive greater precision, fewer byproducts, and a gentler touch with the environment.

Toxicity Research

Brominated alkanes, including 1-bromopentane, concern both environmental scientists and occupational physicians. Exposure experiments in animals reveal moderate acute toxicity, with irritant effects most prominent. Chronic tests suggest prolonged contact can raise organ toxicity risk or sensitize certain tissues, though the compound doesn’t linger or bioaccumulate with the persistence of some heavier halides. Regulatory reviews focus on routes of exposure and proper ventilation or containment. Teams keep refining knowledge, updating workplace exposure limits and dissecting metabolic transformation routes that lead to safer handling in both the lab and larger industrial spheres.

Future Prospects

The story of 1-bromopentane isn’t static; it evolves along with synthetic priorities and regulatory frameworks. Renewed emphasis on green chemistry signals opportunities for designing waste-minimized production processes and tailoring reactivity with reusable catalysts. Researchers hope to tap enzymatic approaches or non-halogenated alternatives where possible, yet few compounds match its versatility for direct, reliable alkylation. Its presence across fine chemicals and teaching labs gives it staying power, yet ongoing studies in recyclability and accidental release prevention push both industry and academia toward smarter stewardship. The next chapter will likely be driven by a mix of resourcefulness, safety, and curiosity.

A Closer Look at This Useful Compound

If you’ve spent any time in an organic chemistry lab, you’ve probably run into 1-Bromopentane. This colorless liquid with a strong, sharp odor has built a solid reputation in both academic and industrial circles because it’s a straight-chain alkyl bromide. Its structure—five carbons in a row capped by a bromine—means chemists can depend on it as a building block. Why does it matter? Synthesis often starts or stops with reliable stepping stones, and 1-Bromopentane provides just that.

Training Chemists and Fueling Innovation

Undergraduate chemistry labs sometimes feel repetitive, but there’s a reason a professor asks you to reach for this bottle. 1-Bromopentane works as a standard reagent for teaching classic nucleophilic substitution reactions. Pour it into that round-bottom flask with sodium cyanide or potassium iodide, and you’ll see how easy it is for the bromine atom to leave, letting the next group latch onto the carbon chain. In my early days of teaching, a well-timed success with 1-Bromopentane often turned quiet students into confident experimenters, ready to try bigger, bolder syntheses.

Taking Synthesis Beyond the Classroom

The story doesn’t end in college. In industry, chemists look for compounds that let them carefully extend or alter molecules. Here, 1-Bromopentane shines as a starting material for making amines by the Gabriel synthesis or adding five-carbon chains to larger molecules through Grignard reactions. Building custom surfactants, fine-tuning pharmaceuticals, or even preparing specialty polymers—all these applications pull from the same source. Reports from chemical manufacturers consistently point to these uses, and the global research community publishes hundreds of studies every year showing new tricks for this old compound.

Environmental and Safety Concerns

Every benefit brings a set of challenges. Like many alkyl bromides, 1-Bromopentane brings risks that call for careful handling. Accidental spills or mishandling can lead to skin irritation or inhalation hazards. On a larger scale, unchecked release into the environment may threaten aquatic life or disrupt soil health. OSHA and the EPA lay out clear rules for storage and disposal, but labs sometimes cut corners or underfund their safety training, especially in smaller facilities or resource-strapped research groups. In the long run, that shortsightedness costs everyone.

Paths Toward Responsible Use

The chemistry community holds the responsibility to take chemical stewardship seriously. Upgrading ventilation, swapping in gloves with higher resistances, and designing safer reaction protocols all reduce risk. Educators play an important part by teaching future scientists about safe practices with toxic reagents. Industry leaders should commit to transparency in the supply chain and invest in greener alternatives where possible. Recent trends show that some companies are now exploring bio-based routes to similar compounds, aiming to cut back on hazardous byproducts from classic halogenation processes.

Building on a Strong Foundation

My experience tells me that 1-Bromopentane won’t disappear from labs anytime soon. Its reliability fuels important discoveries and learning moments. The next stage calls for balance: appreciating what this molecule offers, handling its risks with respect, and investing in smarter, safer strategies for the future. The world keeps moving, and so does the chemistry behind it.

Understanding the Formula

1-Bromopentane holds the molecular formula C5H11Br. One can break that down: five carbon atoms, eleven hydrogen atoms, and a single bromine atom. Each unit in this formula tells a story—years of research and practical use in laboratories across the world. Growing up in a family where chemicals found space in the garage and dinner talk, I learned early how each atom counts in a compound’s behavior.

In 1-Bromopentane, those atoms form a straight chain, which chemists call a linear alkyl bromide. The bromine atom latches onto the end carbon. This detail might sound trivial, but this position fundamentally shifts how the compound interacts with other molecules.

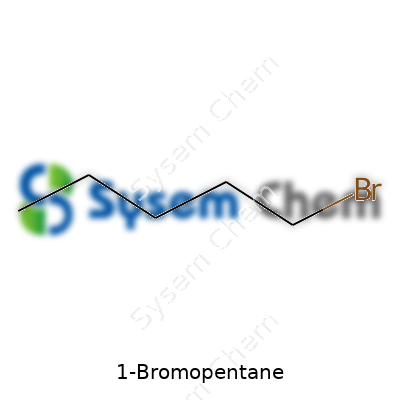

Visualizing Its Structure

Looking at its structure, visualize a straight chain of five carbon atoms. Hydrogens fill up the remaining spaces, keeping things stable, except for the spot where bromine steps in. Drawing it out, the backbone stretches as CH3-CH2-CH2-CH2-CH2Br. The bromine substitutes for a single hydrogen at one end.

Why mention this seemingly simple picture? That arrangement—bromine swapping in at the terminal carbon—shapes the compound’s entire reactivity. Like a door handle only working on one side, this feature means chemists can predict how 1-Bromopentane will behave when introduced into certain reactions. That's real power for anyone working in organic labs, especially for those gearing up for a new synthesis or introductory teaching labs.

Importance for Industry and Research

Manufacturers use 1-Bromopentane as a starting point for making bigger, more complicated molecules. Pharmaceutical development, for example, needs building blocks like this. Researchers rely on its predictable structure to test new catalysts or prepare alcohols and amines—the backbone for so many essential drugs.

From experience in college labs, nothing taught structure-reactivity relationships better than handling these straight-chain halides. Only after mixing 1-Bromopentane with strong nucleophiles did I really appreciate its value. It reacts in classic substitution reactions, letting you swap out bromine for something useful. That’s a practice run for the methods industrial chemists use every day to craft flavors, fragrances, or new drug candidates.

Potential Risks and Handling Issues

Every story has a dark side, and chemicals like 1-Bromopentane bring their own headaches. The bromine attached to the chain means extra caution in handling and disposal. Volatile compounds drift through the lab, prompting headaches or worse without proper fume hoods and ventilation. This safety aspect ties directly back to the formula and structure—bromine in organics creates volatility and toxicity risks. Real-life incidents where careless handling led to lab evacuations convinced me that respect for these molecules doesn’t come from textbooks alone.

What Could Improve?

To reduce those headaches, the push for greener, safer alternatives in organic synthesis has driven research into less toxic halide sources and new reaction conditions. Waste disposal remains on the radar for regulators and chemists alike, since halogenated byproducts demand responsible management. Everyday improvements, such as better ventilation, proper gloves, and safer substitute chemicals, lower the risks.

Grasping the formula and structure of chemicals like 1-Bromopentane isn’t just a classroom exercise. It shapes the compound's use and treatment, especially as industries, schools, and regulators look to balance tradition with safety and progress.

Understanding the Risks

Anyone who has spent time in a chemistry lab knows that not all liquids in glass bottles offer the same level of threat. 1-Bromopentane demands respect. If you’re not careful, a careless splash or accidental whiff can become a big problem. The risk isn’t theoretical—skin contact causes irritation, inhalation brings coughing and headaches, and swallowing even a small amount leads to serious harm. Stories float around workplaces of burnt hands and red eyes, all traced back to skipping gloves or dropping a mask for “just a moment.” Safety rules are written in response to real injuries, not hypothetical dangers.

Personal Protective Equipment (PPE): Your Best Defense

Rubber gloves aren’t just for formalities; 1-Bromopentane gets through thin fabric and eats at bare skin. I’ve seen coworkers grab a flask barehanded and walk away with raw, stinging fingers that remind them all week to gear up next time. You want gloves made of nitrile or neoprene, not latex, since brominated solvents slip through cheap protection. Eye protection isn’t optional either. All it takes is a small splash to turn a student experiment into a trip to urgent care. Lab goggles—nothing less—form a solid barrier.

Work in the Fume Hood

Ventilation makes all the difference. Fume hoods aren’t just expensive furniture; they protect your lungs from dangerous vapors. Most folks in the lab can recall days where a lingering smell meant someone ignored the hood and exposed everyone around them to unnecessary risk. 1-Bromopentane evaporates quickly, and the vapors drift through a room faster than you might think. Working directly under a running hood keeps the air safe to breathe and ensures the rest of the crew doesn’t share in your exposure.

Safe Storage and Handling Practices

Leaving bottles uncapped or sitting open on a bench invites trouble. Tightly sealed containers, labeled with proper hazard warnings, go a long way in preventing mishaps. Storing the chemical away from heat, spark sources, or sunlight prevents dangerous decomposition or fire risks. I’ve seen a spill once from a poorly closed bottle and watched a puddle eat through a plastic bench mat like it was nothing—cleanup becomes a lot harder after that.

Clean Up and Emergency Protocols

If a spill happens, don't grab paper towels and hope for the best. Genuine lab spill kits contain absorbent material and neutralizers for halogenated liquids. Nobody likes false alarms, but knowing the location of eyewash stations, emergency showers, and ventilation controls can make all the difference. After any exposure, even a drop, washing thoroughly with lots of water saves you days of irritation. Reporting incidents—no matter how minor—helps fix gaps in training or equipment before someone gets seriously hurt.

Training and Real-Life Vigilance

Lab safety isn’t just about reading the rules once. Regular refreshers, demonstrations, and sharing real experience reinforce why the precautions matter. It’s not about paranoia; it’s about respect for the chemicals and care for the people. If something feels off, calling attention to it or stopping the work saves stress and avoids hospital visits. Clear, practiced protocols and solid habits turn potential hazards into just another safe day at the bench.

Understanding Why Proper Storage Makes a Difference

1-Bromopentane brings a set of challenges much like many small organic chemicals. Its flammability and slight volatility give it some risk in a lab or storeroom. Over the years, I’ve seen what happens when these facts get ignored—sticky residue on benchtops, odd smells in storage cabinets, or, in worse cases, compromised health for people working around it. Storing this chemical calls for solid attention to the basics. Keeping it in a tightly sealed glass container—polyethylene often leaches or degrades with halides—helps slow down any vapor leaks and blocks air or moisture that could cause it to degrade or form harmful byproducts.

Temperature and light influence the stability of 1-Bromopentane. Direct sunlight speeds up unwanted reactions; long exposure even in ambient lab light can promote discoloration. A shaded, cool space—ideally between 2-8 degrees Celsius—helps maintain shelf life and cuts down on decomposition. Limiting access to trained staff also prevents accidental spills and tampering, lessons quickly learned after mishaps in student labs.

Direct Health and Environmental Concerns

Coming in contact with 1-Bromopentane doesn’t just mean a smelly shirt or sticky hands. Inhalation can cause dizziness, respiratory problems, and long-term exposure links to nerve issues. Skin absorption is real, and splashes easily irritate eyes and mucous membranes. I always keep splash goggles and thick gloves nearby after seeing just how quickly it stings if spilled.

Improper disposal leads to major headaches—not just local contamination, but long-lived pollution. Brominated hydrocarbons don’t break down quickly. Pouring leftovers down the drain sends them into waterways or treatment facilities unequipped for such compounds. Pouring onto soil or tossing in the trash contaminates groundwater or exposes waste handlers to harm. Bigger spills in crowded urban settings even reach air vents and drift into homes and schools.

Practical Steps for Staying Safe

For long-term storage, use amber glass bottles with tight Teflon-lined caps to keep out air and moisture. Label each bottle with clear hazard warnings and the date opened. Place bottles on secondary containment trays, far from acid, base, or oxidizer cabinets. Even in regulated facilities, plenty of accidents start from storing incompatible chemicals together. Keep a spill kit close—absorbent pads, neutralizing agents, and high-efficiency respirators all have a place in cupboards where 1-Bromopentane sits.

For disposal, talk with a licensed chemical waste contractor. Collect all unwanted liquid in closed glass containers—never in makeshift plastic jugs—which resist bromide attack. Label each bottle with the exact compound name and concentration, following local hazardous waste laws. If you run a lab, regular waste pickups cut down on storage time. In places where hazardous waste guidelines seem loose, push for better training, storage, and periodic safety audits. After years around labs, I’ve seen small investments in staff education prevent big accidents down the line.

Moving Toward Better Habits

No single person or institution has all the answers for chemical safety, yet real improvements come from sharing experience and supporting strong policies. Storing and disposing of 1-Bromopentane the right way keeps people healthy, limits pollution, and protects companies from liability. Investing in proper storage supplies, waste management partnerships, and clear staff training isn’t just bureaucracy—it turns chemical safety into a routine, everyday practice.

Boiling Point and Why It Matters

If you’ve ever worked with organic solvents, you notice pretty fast that boiling point decides a lot about how a chemical behaves in everyday lab situations. 1-Bromopentane boils at about 130°C. That gives you some room to maneuver, especially compared to lighter halides like bromoethane, which boil way earlier. No surprise, organic chemists and even industry folks often reach for this compound when they need something that sticks around in a reaction mixture a little longer before turning into vapor. Boiling points should never be dismissed as a dull property — they tell us if something will easily escape a container, how to distill it, and how dangerous it gets around heat sources.

One of my early experiences in the lab showed how a careless approach to boiling point can lead to headaches. We had a flask of pentyl bromide on a hotplate, expecting it to gently reflux. Someone cranked up the temperature too far and filled the fume hood with thick, irritating fumes in seconds. That tells you: Even at 130°C, things can go sideways fast. Companies that handle this solvent in bulk know to engineer proper ventilation and cooling, always respecting that physical property.

Melting Point and Storage Realities

1-Bromopentane doesn’t freeze solid until about -90°C. That makes it a liquid under almost any storage condition found outside of a deep-freeze or a Siberian winter. For manufacturers, that means drums or bottles rarely end up with solidified chunks, and lab workers avoid time-consuming thaw cycles before measuring or transferring it. I once left a bottle near a window on a freezing January day—the liquid never showed a trace of crystallization. Hydraulics, flow systems, and even plain shipping logistics become simpler when dealing with a liquid that stays liquid in just about any weather.

Solubility and What It Reveals

Bring 1-bromopentane near water, and you’ll see two layers. Its solubility in water is practically nil—about 0.32 grams per liter at room temperature. That’s not hard to understand given its five-carbon chain. The molecule acts more like an oil than a salt. In practice, that feature determines waste handling, clean-up protocols, and which reaction work-ups go smoothly. Pulling a product out of a water-based mixture? 1-bromopentane will drag your target compound right into the organic layer, exactly where you want it.

This property can turn into a headache around waterways and the environment. Poor water solubility means it can settle into sediments or stick around in soils a long time. According to studies, similar brominated hydrocarbons can persist, affecting microorganisms and larger ecosystem players. That pushes chemists, manufacturers, and regulators to keep a close eye on waste streams and push for closed-loop systems or incineration instead of down-the-drain disposal.

Balancing Risks, Benefits, and Next Steps

Understanding physical properties like these doesn’t just fill out a safety data sheet. It’s about picking the right solvent or reagent based on what the process demands, planning safe waste handling, and protecting people and the environment. Training sessions I’ve attended always spend extra time on these basics—knowing the boiling, melting, and solubility numbers can mean the difference between a safe, productive workflow and a costly mistake. People tend to brush past those tables in textbooks, but out in the real world, these physical properties set the rules for how the game is played.