Bromoacetyl Bromide: Deep Dive into a Reactive Reagent

Historical Development

Bromoacetyl bromide has a story that goes back over a century, rooted in the early days of organohalide chemistry. Chemists started chasing new sets of molecules to drive transformations that simple acids and bases could never achieve. By the early 20th century, researchers looked for more active acylating agents, and bromoacetyl bromide emerged as a strong candidate. Its discovery gave labs a push toward faster, more targeted reactions, especially where both acylation and halogenation in one step save time. As chemistry teaching moved into the second half of the 1900s, this reagent became a textbook example for challenges found in classic organic experiments, usually reserved for those who wanted to push further in intermediate synthesis.

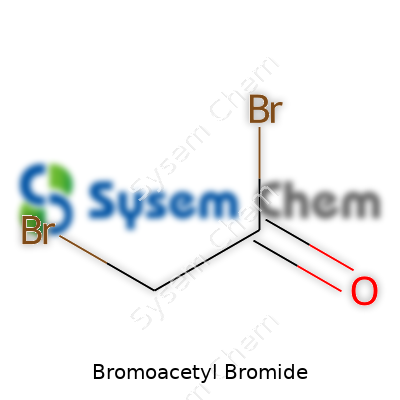

Product Overview

Bromoacetyl bromide (known to many as BAB) carries the formula C2H2Br2O, giving off a sharp, irritating odor. Its clear, pale-yellow liquid form looks innocent but reacts fiercely with water and most bases. Chemists stock it in small, tightly sealed containers, keeping it far from ambient moisture. Acylation and halogen introduction step up in complexity when using reagents like this, offering new tricks for synthesizing pharmaceutical intermediates, small-molecule libraries, and reagent building blocks. With every use, chemists understand that a little goes a long way, not just because of its reactivity, but also due to its volatility and toxicity.

Physical & Chemical Properties

At room temperature, bromoacetyl bromide stays liquid, even though it can turn volatile in a warm or poorly ventilated lab. Its boiling point hovers near 129-132°C, but strong fumes start filling the air long before that point, pushing the need for careful handling. Water never gets along with this compound, and even a bit of moisture ignites a violent, smoky reaction. Its dense makeup, around 2.48 g/cm³, makes it much heavier than water. Its chemical structure brings together a carbonyl group set next to two bromines, baking in strong electrophilicity and reactivity. Any chemist who comes close recognizes its difficult side—fumes cause tears and it etches glassware if left unchecked.

Technical Specifications & Labeling

Industry labeling for bromoacetyl bromide emphasizes its acute hazards. Each bottle features clear pictograms for toxicity and corrosiveness, and most suppliers include signal words like “Danger” front and center. Concentration hits nearly 98-99% for research grade, and labs demand certificates of analysis to match. Safety data sheets highlight which respirators, gloves, and splash goggles stop the worst of the exposure. Transportation leans toward UN 1731: the code for acyl halides, corrosive and volatile. Chemists depend on this attention to detail for both compliance and personal safety, not just to avoid fines but because one slip ends a day in the fume hood or far worse.

Preparation Method

In most cases, labs prepare bromoacetyl bromide by treating bromoacetic acid or bromoacetyl chloride with phosphorus tribromide (PBr3) or thionyl bromide. Each method turns a carboxylic acid group into an acid bromide, while shoving in a second bromine atom for maximum reactivity. Heating ramps up as the reaction fights to completion, sending out pungent fumes from both product and byproduct. Yields reach high percentages when using strict anhydrous conditions and slow addition under cooling. Outside academic synthesis, specialty chemical firms scale up the reaction, using closed reactors, automated feed systems, and rigorous monitoring to control heat buildup and gas release.

Chemical Reactions & Modifications

Bromoacetyl bromide works as a versatile acyl donor and alkylating agent. During nucleophilic reactions, its acyl bromide group attaches smoothly to amines, alcohols, and thiols, while the nearby bromine atom can slip off and trigger more changes in the substrate. Peptide chemistry sometimes employs this reagent for site-specific modification, switching functional groups with a simple, direct transfer. Arylation, amidation, and O-acylation take place rapidly, often outpacing less reactive cousins like acetyl chloride. In building blocks for agrochemicals or pharmaceuticals, chemists use its powerful reactivity in both early-stage and late-stage functionalization—sometimes as the only reasonable route to molecules that resist other methods.

Synonyms & Product Names

This compound shifts names depending on context and supplier catalog. Many chemists call it “bromoacetyl bromide” or “acetyl bromide, bromo-,” while globally, synonyms like “2-bromoacetyl bromide” or “bromaceyl bromide” pop up. Commercial catalogs play it simple, often shortening the name to BAB. Despite the varied names, all suppliers reference the same IUPAC short name, and regulatory IDs like CAS 598-21-0 or EINECS 209-936-3 keep things orderly through import, export, and online research.

Safety & Operational Standards

Labs and warehouses treat bromoacetyl bromide with more caution than most acids or halides. Revised OSHA regulations require full-face shields, chemical-resistant gloves, long sleeves, and proper shoes—simple latex or nitrile gloves do not cut it for real exposure. Fume hoods must resuscitate a dozen times an hour, and splash trays or spill kits sit close by. On a larger scale, chemical firms add extra layers: double containment, remote handling, and alarm systems in case of accidental vapor release. If a splash lands, immediate decontamination is the only answer, and response training turns into a real world test under the pressure of dangerous fumes. Waste streams route into neutralization tanks, where sodium bicarbonate and other absorbers break down leftover reactivity before shipping to disposal sites.

Application Area

Pharma and agricultural chemists prize bromoacetyl bromide for introducing both acyl and bromo groups, paving the way for beta-lactam antibiotics, new herbicides, and antifungal candidates. It works as a keystone in library synthesis for drug discovery, speeding up the search for new hits. Some industrial coatings, photoresist chemicals, and adhesives benefit from its ability to anchor specific atoms in place. In specialized R&D, the reagent finds roles in building fluorescent dyes, catalysts, and niche materials where adding two reactive groups sets up new chemical spaces to explore. Targeted side-chain modification, cross-coupling, and cyclization routes call on BAB to get the job done where gentler reagents come up short.

Research & Development

Chemists keep finding novel uses for bromoacetyl bromide, not just because of legacy applications, but also due to changing demands in medicinal and material science. High-throughput screening automation needs quick, harsh reagents, and BAB delivers trait combinations that get attention—speed, selectivity, and downstream diversification. Academic groups run deeper into green solvent optimization, searching for reaction setups that minimize hazardous waste without undercutting yield. Combination techniques with microwave and flow reactors pop up more in peer-reviewed articles, showing better control of heat and side product formation. In protein modification studies, researchers lean on BAB for rapid pegylation and fluorescent labeling, pushing into fields like proteomics where speed and specificity bring real benefits.

Toxicity Research

A dark side comes with potency: bromoacetyl bromide hits human health hard. Animal studies and accident reports show its vapor quickly causes airway burns, bronchospasm, and long-term lung damage. High lipophilicity sends BAB into tissues fast, while corrosiveness triggers fast necrosis on skin or eyes. Acute exposure numbers lead regulatory offices to set strict permissible exposure limits, with instant evacuation required if vapor containment fails. Mutagenicity and carcinogenicity data remain thin, but most research suggests this class of compounds needs handling as if each drop carries extreme risk. Chronic studies flag organ damage, and even non-lethal exposures can sensitize immune responses. Safety campaigns in teaching labs return again and again to case studies where one cut corner led to hospital visits, reinforcing the message better than any rulebook can.

Future Prospects

Researchers aiming to improve safety and sustainability around bromoacetyl bromide stay busy looking for alternatives and engineering controls. Advances in flow chemistry offer tight, on-demand production, lowering the need to store or ship bulk material. Automation and robotic handling shrink human contact, reducing incidents. Direct replacement with less hazardous surrogates remains a tough challenge in many complex syntheses, where no other reagent delivers BAB’s specific combination of speed and transformation power. Regulators lean into stricter standards, pushing suppliers to provide smaller, tightly managed packaging and precise inventory tracking. Green chemistry groups continue the hunt for routes to generate BAB analogs from less toxic building blocks. For all the dangers, demand persists, fueled by innovation in fields where a short, potent step can chop weeks or save costs across an entire discovery pipeline.

A Glimpse Into the Chemical Toolbox

Bromoacetyl bromide brings sharp utility to certain chemistry labs. I remember the sharp, pungent odor cutting through the fume hood during an old undergraduate synthesis experiment, reminding me that some chemicals demand respect just from smell alone. Handling it made me pay attention, and for good reason. This compound, bearing two reactive bromine atoms, acts as a serious intermediate in organic synthesis.

Sparking Reactions in Pharmaceutical Development

Pharmaceutical research loves tools that offer versatility at the molecular level. Bromoacetyl bromide slips into many synthesis pipelines because it helps chemists tack on bromoacetyl groups. By doing so, it helps create molecules with new properties—something crucial in developing new medicines. Every time a drug company tests a new antibiotic, antihypertensive, or antiviral, there's a long story packed into those early reaction flasks. Bromoacetyl bromide plays a supporting role in many of them.

Let's talk about why this matters. Drug discovery doesn’t run without powerful building blocks. Molecules crafted with bromoacetyl bromide can eventually suppress a virus or lower someone's blood pressure. That line from lab bench to pill bottle is long, but it’s paved with reliable intermediates like this one.

Fuel for Advanced Chemical Synthesis

Bromoacetyl bromide works for more than pharmaceutical dreams. Chemists rely on it when they want to make peptides for research or diagnostic kits. It attaches specific groups onto amino acids—sort of like fitting custom attachments to a bicycle frame so it handles new terrains. Once linked, these altered amino acids set the stage for more elaborate molecules, opening doors for research that helps medical professionals understand diseases at a deeper level.

Research in materials science often taps this compound to form specialty polymers or fine-tuned chemical coatings. Creating such materials helps in everything from electronics to medical devices—each demanding more than off-the-shelf chemistry.

Staying Safe With Potent Reagents

There’s a darker side here. Bromoacetyl bromide isn’t a chemical anyone should treat lightly. Exposure risks include burns, lung damage, and eye injury, even at low concentrations. Regulatory agencies flag this compound as hazardous, and rightfully so. Safety cannot become an afterthought around it. Fume hoods, proper gloves, and goggles aren’t extras—they're nonnegotiable.

Stories from peers working late or cleaning up after accidents stick with me. Quick reactions make all the difference. Training and culture in the lab often matter more than the latest gadget or chemical fume extraction system. The best labs drill their teams in spill response, not just lab technique.

Moving Toward Safer Alternatives

Some groups look for greener substitutes that bring less risk without sacrificing performance. As chemists grow sensitive to the long-term hazards of certain reagents, eco-friendly alternatives begin to show up in papers and conference talks. Reducing dependency on aggressive chemicals like bromoacetyl bromide helps cut down on workplace accidents and makes chemical production cleaner for the environment.

That path won’t erase bromoacetyl bromide overnight. For specific transformations, its role remains tough to replace. But as technologies evolve, safer options gain traction, particularly as the next generation of chemists demand improved workplace health.

Bromoacetyl Bromide: A Real Threat in the Lab

Bromoacetyl bromide doesn’t give anyone a second chance. This chemical sits near the top of lists for corrosive, volatile, and highly reactive lab substances. Breathing in its fumes or letting a drop land on your skin can send you to urgent care. I remember my early days in the chemistry lab, watching a senior fumble with a carelessly capped bottle. He barely caught the slip before a drop leaked. Nobody laughed. The message stuck: respect is not optional.

Personal Protective Equipment: The Bare Minimum

PPE offers the best shield in hands-on chemistry. Goggles, a face shield, and a fresh lab coat make up day-to-day armor. Standard disposable gloves won’t cut it; thick nitrile or Viton gloves hold up much longer. If you feel the biting scent, your mask isn’t good enough. A proper organic vapor respirator should fit snug, never sliding down. Large spills or splash risks demand a chemical-resistant apron. Just washing your hands afterward won’t reverse an accident.

Storage Musts: Out of Sight and Out of Range

Leaving bromoacetyl bromide on the main bench or next to the sink marks a rookie mistake. It needs a cool, dry, well-ventilated, and locked cabinet. Acid-resistant shelving is a must, far from anything containing water or bases. Even vapors can drift and start reacting with nearby containers. I once saw a jar stored close to an open bottle of ethanol. After a few minutes, the air burned to breathe, but worse, the containers began weeping at the seams. This isn’t hypotheticals—bad storage choices really do set up dangerous chain reactions.

Ventilation and Engineering Controls

Fume hoods act as the first line of defense. They suck away vapors before they drift into the work area. Anyone who’s handled bromoacetyl bromide out in the open knows the choking sting well. Strong hoods, maintained often, save lungs and lives. Splash shields in front of setups, backup spill trays beneath, and tightly-sealing waste containers keep accidents from turning disastrous.

Handling: Discipline Over Convenience

Never open these bottles in a rush. Use secondary containers to catch any drops or spills. Pour out only what’s necessary, and clean the bottle necks before putting the cap back. Label everything. A simple “corrosive” tag can save someone else from losing a finger or an eye. I keep spill kits within arm’s reach, not tucked away across the room.

Emergency Response: Fast and Sure

If bromoacetyl bromide touches your skin, immediate, high-flow water rinsing—preferably in a safety shower—counts as the only real solution. Splash in the eyes? Go straight to the eyewash, no matter how awkward it feels. All labs must have up-to-date antidote and eyewash kits. Medical attention comes next—don’t waste time trying to handle it on your own.

Training and Habit Make the Difference

Seasoned chemists keep refresher drills on hand. Reading a chemical safety data sheet isn’t busy-work; it’s the best way to avoid “learning the hard way.” Labs must drill their people on what to do if a bottle breaks or someone inhales a lungful of fumes. The best safety measure grows from habit—constant double checks, a touch of paranoia, and speaking up when something seems off. Every day someone cuts a corner with hazardous chemicals, accidents wait to happen. Staying safe with bromoacetyl bromide starts with listening to those who’ve dodged its worst outcomes—and never giving it the benefit of the doubt.

Looking at the Risks Up Close

Bromoacetyl bromide sounds like something out of advanced chemistry, but it's a real tool in the hands of researchers and chemical manufacturers. I remember getting briefed during my organic chemistry training—this was one of those bottles they always kept locked up. There’s good reason for that. This chemical doesn't just sting your nose; it’s a nasty corrosive that releases toxic fumes and reacts violently with water. Leaving it out or storing it wrong isn’t an option. Even in a lab with safety protocols, accidents happen. You don’t want to take shortcuts on this one.

Temperature and Environment Matter

Heat and sunlight trigger changes in bromoacetyl bromide, making it even more risky. A dedicated chemical fridge or a cool, well-ventilated storage room saves you a load of trouble. Ordinary shelving won’t cut it. Fluctuating room temperatures push up vapor pressure, bumping up the risk for leaks or—worse—bottle breakage. I’ve seen broken containers after a power cut where the air conditioning failed. Cleaning up after something like that takes hazmat training, not just a mop and bucket.

Keep It Away from Water—Always

Every chemistry teacher hammers home: water and bromoacetyl bromide don’t mix, not even a splash. Contact with moisture creates corrosive hydrobromic acid and choking fumes. Proper storage calls for keeping it in a tightly sealed container, often under dry, inert gases like nitrogen. Humidity ruins seals and damages packaging, too, so a dry cabinet goes a long way for peace of mind.

Container Choices Are Critical

Some folks grab whatever glass bottle is handy, but that approach risks disaster. Fresh, corrosion-resistant glass with robust sealing works. Strong rubber or Teflon stoppers last longer and won’t decay. A worn-out cap ruined with acid corrosion will only last so long before it leaks. Label those bottles with hazard warnings, date of receipt, and the responsible handler’s name. During my time in research, tracking who last handled the compound always increased accountability and helped prevent mix-ups.

Separation from Incompatibles

Bromoacetyl bromide can’t go near bases, strong oxidizers, and water-reactive materials. It only takes a mix-up to trigger a dangerous reaction, especially in a crowded storage area. I recall a colleague’s mistake: storing reactive chemicals together “just for a few hours.” That shortcut led to an emergency evacuation. Segregated cabinets marked for corrosives, along with an updated inventory, create that buffer that makes all the difference.

Training and Emergency Planning

No safety plan works without trained eyes watching. Lab staff must know how bromoacetyl bromide acts and what to do during a spill. Safety data sheets need to stay updated and within reach—having information about first aid, fire-fighting methods, and spill response can save lives. Personal protective equipment cuts down risk. In my experience, well-practiced drills made even complex emergencies manageable. Local fire departments appreciate accurate chemical inventory lists and maps of your storage system to speed up response.

Moving Forward with Responsibility

Proper storage goes beyond rules—it’s about caring for everyone in the building. Bromoacetyl bromide demands respect, thoughtful handling, and an eye for small details. Choosing dry, secure storage, effective labeling, and clear communication helps prevent expensive and dangerous mishaps. Every time I pass a locked chemical cabinet now, I remember not just rules, but stories from labs where small mistakes found a way to cascade. Staying vigilant doesn’t take extra courage—it’s just good sense.

Chemical Formula: Simple Structure, Big Responsibility

Bromoacetyl bromide answers to the formula C2H2Br2O. This speaks to its simplicity: two carbons, two hydrogens, two bromines, and one oxygen. For anyone working in labs or handling reagents, being exact with these details avoids dangerous mistakes. Mislabeling a chemical means risking improper storage or unsafe handling—both of which can lead to accidents. So, knowing these numbers isn’t just for scientists scribbling in notebooks; accuracy keeps people and data protected.

Molecular Weight: 201.85 g/mol

The molecular weight for bromoacetyl bromide is 201.85 grams per mole. It’s not just a number tucked in a textbook somewhere. If you’re mixing reagents or scaling up a synthesis, this weight tells you how much material is in your flask. I’ve worked with organic chemicals, and calculations based on the wrong molecular weight waste resources—and sometimes even ruin an entire batch. Being off by a few grams in synthesis might cause a chain reaction of errors, from product loss to financial costs that stack up faster than most folks realize.

Relevance in the Lab and Beyond

Bromoacetyl bromide doesn’t hang around every lab bench, but it turns up in places where chemical synthesis gets serious. It’s a strong acylating agent, valued for introducing the bromoacetyl group into target molecules. This kind of precision is required for building certain pharmaceuticals and fine chemicals. The two bromine atoms make it reactive, so care during use becomes rule number one. I’ve seen situations where even a small spill created fumes intense enough to clear out a whole room—ventilation and personal protective equipment aren’t just suggestions with this compound.

Handling Hazards and Safety Strategies

Saying this chemical is “hazardous” risks understating the facts. It reacts violently with water, releasing hydrogen bromide—a caustic gas. Skin contact can cause severe burns, and inhaling vapors harms the respiratory system. The rules here are clear: work in a fume hood, wear nitrile gloves, goggles, and a lab coat, and make spill kits easy to access. Training should focus on preventing exposure and quick response, not just memorizing facts from a safety sheet. Many labs institute a buddy system—another pair of eyes reduces the chance of shortcuts and mistakes. Safety isn’t just policy, it’s habit.

Environment and Waste: No Room for Complacency

Improper disposal of bromoacetyl bromide can damage ecosystems and water supplies. This chemical never belongs down a drain. It demands specialized waste containers and prompt collection by certified professionals. Careless disposal practices have led to environmental violations and fines, dragging down both research budgets and reputations. Every researcher should know local and federal chemical waste laws and act before situations escalate out of control. Sharing stories in group meetings—trade secrets aren’t at risk, but awareness always wins.

Moving Forward: Attention to Detail Matters

Crafting safer labs and smarter handling habits starts with information like formula and molecular weight. It’s not about filling out paperwork—it’s about making sure every researcher goes home healthy and the work stands up to scrutiny. With chemicals like bromoacetyl bromide, even a single oversight can erase months of progress. Respect for detail shapes tomorrow’s breakthroughs and keeps risk out of the picture.

Diving Into the Problem

Dealing with bromoacetyl bromide isn’t about guts. It’s all detail. This chemical kicks out a real punch. It’s a strong lachrymator, which means it can sting eyes and choke lungs within seconds. Some years back in a graduate lab, I watched as a single drop made three of us reach for eyewash and fresh air. Nobody reading safety data sheets ever thinks panic is around the corner, but the truth is, that panic comes fast.

Why Quick Action Saves

The stuff is volatile, turning into dangerous fumes even on a cold day. No one in a research setting should ever open a bottle of bromoacetyl bromide unless a fume hood’s running well and gloves, goggles, and a coat are in place. Mistakes happen anyway. Maybe a cap slips, maybe a beaker tips. Suddenly, exposure isn’t theory anymore. Breathing even low concentrations can lead to coughing, burning eyes, and in the worst cases, lasting lung injury. Letting hours go by before reporting an exposure is asking for real trouble. Hospital data from chemical accidents show up to half of severe exposures happen not from the chemical itself, but from slow responses or improper cleanup.

What To Do the Moment a Spill Happens

Drop what you’re doing. Evacuate anyone without protection. Don’t try heroics or grab paper towels—call for help, ideally a hazmat or trained emergency team. This isn’t nail polish on the floor. Bromoacetyl bromide reacts viciously with moisture, even that tiny bit in the air, giving off harsh acids and chemical byproducts that make a bad scene worse. The best labs store spill kits built for acid halides nearby. Those kits pack appropriate neutralizers and absorbents—usually materials like sodium bicarbonate, not just sand or clay.

Covering the spill (without leaning over it) with this absorbent contains vapors. Anything else risks spreading contamination. Windows stay closed to keep fumes controlled—turn on exhausts and fans built for this work instead. If the liquid hits skin or eyes, immediate flushing with running water can be the difference between full recovery and hospitalization. University safety officers and experienced chemists always say: use the eyewash or shower for twenty minutes, not a quick rinse. It’s uncomfortable and cold. It works.

Long-Term Safety Culture

After the crisis, forgetting about the spill is easy. That's a trap. Every event makes a team stronger or sloppier. Honest discussion—walking through exactly where things went wrong—helps set up better barriers, improved labels, and smarter habits. Labs or businesses storing bromoacetyl bromide should run regular drills, not just boring checklists, but real-world simulations. I've watched teams catch mistakes only when testers hid unlabeled bottles around the workspace and asked for a step-by-step spill response.

Bromoacetyl bromide isn’t just a chemical you “work with.” It’s one you respect or pay for in burns, injury, or worse. Building safer workspaces takes leadership, resources, repeated training, and personal investment. Health and safety officers must do more than regulations—they foster a mindset where no shortcut is worth the fallout. If you end up near bromoacetyl bromide, preparation, attention, and speed are your only friends.